Urban Umbrella

Overview

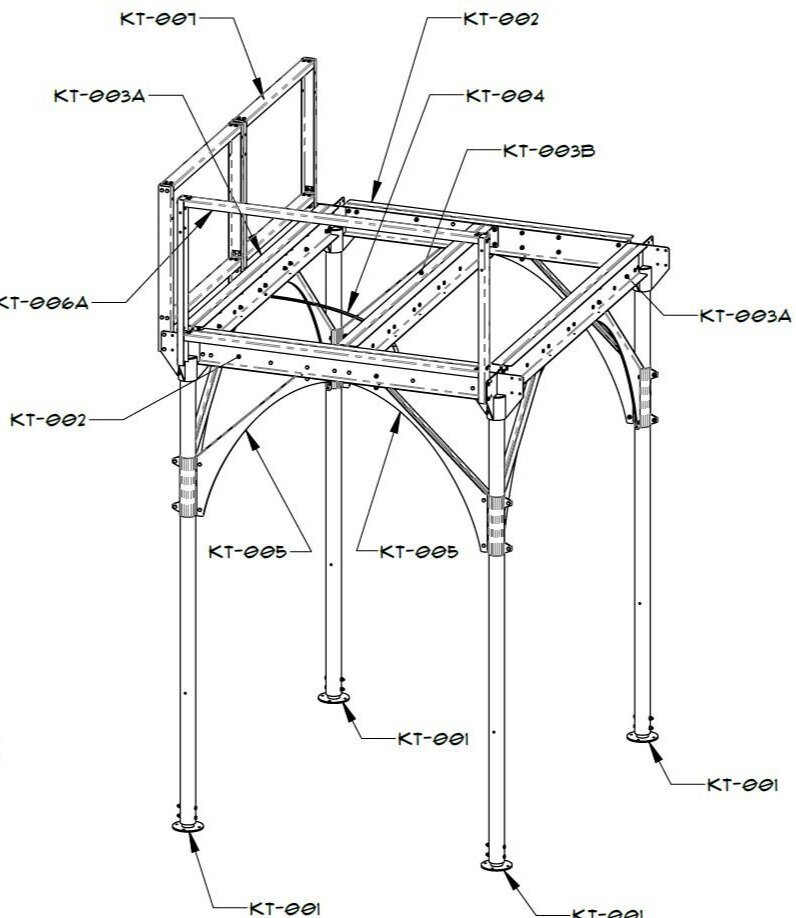

As the Director of Product Development, I have modernized Urban Umbrella’s product to be more flexible and economical while maintaining its architectural elegance and structural integrity. Using my intuition as a designer and education as a mechanical engineer, I have worked with our engineers and fabricators to develop a new design strategy: minimize the number of welded parts and simplify the majority of our components to be made out of the same stock material—12 gauge steel. The reduction in weldments and increased use of sheet steel cut overall production cost by 50% and allows us more flexibility to adapt to any width of sidewalk.

Design Development:

Urban Umbrella is disrupting the sidewalk shed market. As its head of design, I am constantly pushing the product to be better for customers, easier to install, and cheaper to produce. I understand the clients’ aesthetic needs as well as our construction costs, so I am able to innovate with both in mind. The resulting designs are uncompromising in providing maximum benefit to the customer while minimizing production costs and simplifying the installation.

Production to Installation:

As the lead designer, it is my responsibility to model, produce, and verify the drawings used for engineering and production. I also oversee project plan and detail drawings for official submissions and installation sets. Understanding a design from conception through technical drawing, production, and installation allows me to design efficiently to streamline the process between the various phases.

Project Management:

For all installations in NYC, I have been the on-site supervisor in charge of coordinating inventory logistics, overseeing contractor installation, insuring contractor and pedestrian safety, and serving as the point of contact for our clients. Having on-site experience has sharpened my organization and coordination skills and my ability to communicate with both clients and contractors.